CarboxyethylIsothiuroniumBetaine with the CAS number 5398-29-8 under the brand name Malpanol NATPN. We manufacture and export the product articularly effective as a class I brightener for nickel and nickel-iron alloy electroplating baths. Its similar names are 3-carbamimidoylsulfanylpropanoic acid; S-Guanyl-thiohydracrylsaeure.

Technical Data Sheet of Carboxyethyl Isothiuronium Betaine

Revision No.: 1

Revision Date: 01 / 2019

| Product Name | Carboxyethyl Isothiuronium Betaine |

| Trade Name | Malpanol NATPN |

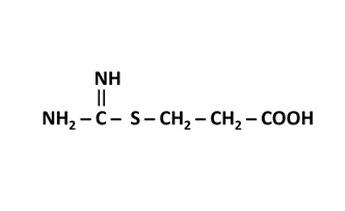

| Molecular Formula | C4H8O2N2S |

| Molecular Weight | 148.2g/mol |

| CAS No | 5398-29-8 |

* Malpanol ATPN is used to produce brightener additives for the electroplating industry.

Synonyms

Malpanol NATPN; Solar ATPN; 3-(Amidinothio)propionic acid; 3-[(aminoiminomethyl)thio]-propanoic acid; 3-Isothioureidopropionic Acid; S-Carboxyethyl isothiuronium betaine (ATPN); S-Carboxyethylisothiuronium Betaine; Propanoic acid, 3-(aminoiminomethyl)thio-; 3-[(Aminoiminomethyl)-thio]-propionic acid; ATPN; S-(2-Carboxy-aethyl)-isoharnstoff; 3-Isothioureido-propionsaeure; S-Carboxyethylisothiuroniumbetaine(ATPN); 3-carbamimidoylmercapto-propionic acid; 3-carbamimidoylsulfanylpropanoic acid; S-Guanyl-thiohydracrylsaeure; 3-Carbamimidoylmercapto-propionsaeure; 3-(amidinothio)propionic acid; CAS 5398-29-8.

| Appearance | White Solid Powder. |

| Odour | Product specific. |

| Purity | 98% |

| Density | 1.49 g/cm3 |

| PH (1% aq. solution) | 5.0 - 6.0 |

| Boiling Point | 323.4 °C |

| Melting Point | Data not available. |

| Flash Point | 149.4ºC |

| Refractive Index | 1.607 |

| Solubility | Malpanol NATPN is well soluble in hot water. |

| Stability | Stable under recommended storage conditions. |

| Malpanol ATPN is used to produce brightener additives for the electroplating industry. |

| It is particularly effective as a class I brightener for nickel and nickel-iron alloy electroplating baths and as a brightener for copper plating. |

| Impurity tolerance, to improve cover capacity in low current area in Nickel plating. |

| Malpanol NATPN has a shelf life of twelve months in sealed containers. |

| HDPE drum packaging (we can package depending upon customer requirements, e.g. 25, 50 or 200kg). |

Note: Information given in this technical data sheet is based on current knowledge and our laboratory evaluation; it is presented as per our opinion without any guarantee. Buyers must carry out their own tests and experiments to determine the suitability and completeness of our products for their use and application.